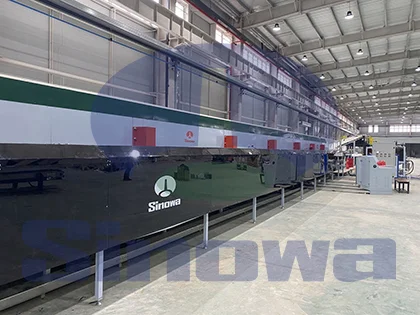

信禾工業(yè)科技「www.shionoe.com」專業(yè)的防火夾芯板生產(chǎn)線廠家,為開平企業(yè)提供防火夾芯板生產(chǎn)線制造和技術(shù)服務(wù)方案。防火夾芯板生產(chǎn)線是Sinowa公司重要的代表產(chǎn)品之一,主要提供于市場的高端集成自動化的各類聚氨酯夾芯板材生產(chǎn)線,我們的客戶遍布世界各地和中國,擁有豐富的生產(chǎn)經(jīng)驗(yàn)。不斷創(chuàng)新、持續(xù)改進(jìn)的技術(shù)理念,讓我們的生產(chǎn)線各項(xiàng)綜合指標(biāo)始終處于市場的較高水平。

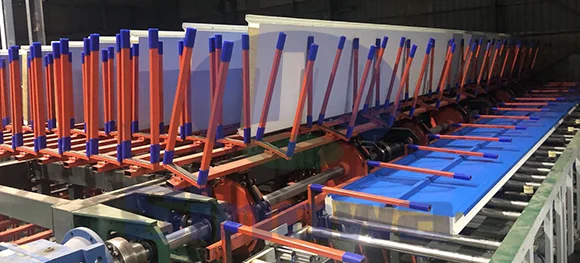

基于不斷進(jìn)取的技術(shù)追求,Sinowa研發(fā)的防火夾芯板生產(chǎn)線為您提供高效率的產(chǎn)業(yè)價值,立足中國成本優(yōu)勢和我們努力的技術(shù)理念,讓我們的生產(chǎn)線擁有全球優(yōu)先的性價比優(yōu)勢。聚氨酯夾芯板材生產(chǎn)線可以滿足客戶多種生產(chǎn)需求,模塊化的整線設(shè)計理念,讓我們的所以部件都能整線兼容,并隨意組合。通過不同的組合和配置選擇,經(jīng)過簡單的切換,我們的生產(chǎn)線可以很方便地自動化生產(chǎn)屋面夾芯板,墻面夾芯板以及冷庫夾芯板等多種產(chǎn)品,內(nèi)部芯層可以是聚氨酯,也可以是巖棉,玻璃棉等不同品種。生產(chǎn)線具備很高的適應(yīng)性,可以生產(chǎn)PU,PIR及巖棉系統(tǒng)各類夾芯板,能夠根據(jù)客戶需要設(shè)計多種但含多種配置,迅速滿足客戶需求,價格體系靈活。

高度集成及聯(lián)動的控制體系將所有控制點(diǎn)集中于主控中心,實(shí)現(xiàn)整條防火夾芯板生產(chǎn)線控制的參數(shù)聯(lián)動和故障自診,并可實(shí)現(xiàn)運(yùn)程控制。高水平的自動化控制系統(tǒng)也為客戶節(jié)約了人力和減少人力損耗。 全力解決系統(tǒng)集中控制,采用工藝集中控制思路,機(jī)組所有動作部件的控制系統(tǒng)整合在一個工藝操控臺,遠(yuǎn)距離通訊,提高自動化水平,降低流水線配置人員數(shù)量。采用模塊化設(shè)計的主機(jī),使得生產(chǎn)線運(yùn)轉(zhuǎn)精良,質(zhì)量穩(wěn)定可靠,零部件損耗小,維護(hù)和保養(yǎng)損耗少。整條生產(chǎn)線嚴(yán)格執(zhí)行模塊化設(shè)計,盡可能保證零部件互換,以實(shí)現(xiàn)節(jié)約化生產(chǎn),杜絕手工拼接,全部在加工中心機(jī)上實(shí)現(xiàn)零部件的重點(diǎn)工序完成,零部件檢驗(yàn)入庫后即進(jìn)入裝配狀態(tài),實(shí)現(xiàn)積木化裝配,不但大大提高生產(chǎn)的效率更主要的是可以實(shí)現(xiàn)快速供貨,亦將產(chǎn)品質(zhì)量的恒定可靠提高到嶄新的水平,極大可能將產(chǎn)品質(zhì)量受人為因素的影響降低。

無液壓系統(tǒng)的主機(jī)因采用精密伺服升降機(jī)構(gòu),使得板材厚度控制變得隨心所欲,客戶可以十分方便的改變或調(diào)整板材的厚度,并且不再有液壓系統(tǒng)調(diào)整,泄露,維護(hù)等多項(xiàng)煩惱。 高水平的節(jié)能和防護(hù)設(shè)計,使得整條夾芯板生產(chǎn)線具備四季全天候生產(chǎn)的可能,客戶也不必浪費(fèi)大量預(yù)算,另外建設(shè)隔離保溫房和進(jìn)行環(huán)境加溫,我們的生產(chǎn)線自有的節(jié)能和環(huán)保設(shè)計,可以保證客戶生產(chǎn)線在主要時間內(nèi)自由升溫生產(chǎn),為客戶節(jié)約更多成本。

采用大功率低能耗設(shè)計,防火夾芯板生產(chǎn)線動作反應(yīng)快,能耗低,采用全新的全封閉內(nèi)保溫設(shè)計,盡力將能源消耗控制在較低水平,滿足在室溫5℃以上時加熱及保溫系統(tǒng)啟動后至生產(chǎn)工藝溫度不超過1小時設(shè)計目標(biāo)。能耗相當(dāng)于同類產(chǎn)品的40%。

Dedicated to the research and development of high-end & high-efficiency sandwich panel lines, Sinowa is comprehensively taking the leading position in terms of efficiency, automation control level, HMI, environment protection and energy consumption, with subversive designs made in some critical technological fields to procure exceptional cost performance and customer-friendly experience for the entire pu sandwich panel line. The adoption of system integration technology and bus control technology accomplishes the full automatization of integrated and coordinated control of the entire production line with accessible remote interactive communication. Ranking the first-class level in the world, it is currently the continuous pu sandwich panel line in the market taking a comprehensive lead in high performance.

Based on the continuous technological pursuit, the pu sandwich panel production line developed by Sinowa provides you with high-efficiency industrial value. Based on China's cost advantage and our hard-working technology concept, our production line has a world-leading price-performance advantage. Continuous PU/PIR Sandwich Panel Production Line can meet a variety of production needs of customers.The whole line design concept of modularization enables all our components to be integrated and combined at will. Our continuous pu sandwich panel production line can easily automate the production of roof sandwich panel, wall sandwich panel, cold storage sandwich panel and other products by different combination and configuration selection and siple switching. The inner core layer can be polyrethane or rock wool, glass wool, an so on. The sandwich panel machine has high adaptability, which may produce various sandwich panel of the PU, PIR and rock wool systems.

We may design various products according to the customer’s requirements, including various configurations, so as to meet their demands with flexible price system. Highly integrated and linked control system centralizes all control points at the main central center, achieving parameter linkage, fault self-diagnosis controlled by the whole continuous sandwich panel line and shipping distance control. High-level automatic control system also saves the manpower and reduces the manpower loss for customers. Concentrated system control is fully realized in the practice of concentrated process control so that the control system of all the movements of the parts in the polyurethane sandwich panel line is integrated in one process control console with accessible remote communication to elevate the automation and reduce the allocated number of personnel for the assembly line. The main engine with modularized design achieves the precision operation of the polyurethane sandwich panel production line, stable and reliable quality, less part and maintenance loss.

The whole pu foam production line is strictly modularized in design to ensure the greatest probability for the parts to be interchangeable, making it the most cost- and energy-saving. No joining made manually, all the key processes of the parts are completed in the machining center. As soon as the parts are inspected and warehoused, they enter into the assembly process. The modularized assembly can not only greatly increase the production efficiency but, most importantly, realize quick delivery as well. It elevates the reliability of product quality to a totally new level and minimizes the influence from human factors. The whole pu sandwich panel line has over 40 innovative inventions, making our products have lots of unique features and the comprehensive performance of our production line leading in the industry. The precision servo hoisting mechanism employed by the main engine without hydraulic system makes the board thickness control flexible and the customer may conveniently change or adjust the board thickness. There will be not such troubles as hydraulic system adjustment, leakage, maintenance, etc.

High-level energy saving and protection design makes the polyurethane sandwich panel machine possible to produce around the clock throughout the year and the customer will save huge budget. In addition, the isolated heat preservation room is constructed for warming the environment. The energy saving and protection design of our high-tech sandwich panel lines may guarantee that the customer’s production line may be freely heated and produce in the main time to save more costs for customers.The high-power low-consumption design quickens the reaction of the pu sandwich panel machine while energy consumption is kept low. With the brand-new, fully sealed inner insulation design, the energy consumption is controlled at the minimum level to achieve the design objective of less than an hour for the insulation system to be activated from the room temperature above 5℃ to the production process temperature. The energy consumption is only 40% that of those similar products.